How Circular Fashion is Closing the Loop

The fashion industry has always been tied to glamour, expression, and identity, but behind the runways and the racks is a system that's had a harsh impact on the environment. For decades, fashion was made, used, and thrown away at breakneck speeds, fueling a linear system that delights in excess. A quiet but powerful shift is underway. Consumers are no longer accepting fast fashion at face value. Designers are rethinking the very fabrics they use, and innovators are transforming how we view and handle textile waste as a resource.

This is being replaced by a circular model, one that respects materials, loops back, and redeploys resources. From the technology development facilities of textile-to-textile recyclers to the design labs favouring mono-materials, this revolution is transforming what we wear and how we wear it.

At JB rPET, our mission is to enable this change by providing high-quality recycled PET pellets that are integrated in circular supply chains and drive sustainable innovation.

Textile‑to‑Textile Chemical Recycling

At the heart of circular fashion is Textile-to-Textile (T2T) recycling, a process where discarded textiles are transformed into new fibres or yarns. While the promise is immense, global infrastructure for T2T remains in its early stages. Currently, less than 1% of textiles get fully recycled back into apparel.

By chemically breaking down industrial textile waste and upcycling it into polyester resin, we're enabling truly circular fabric production at scale. The T2T value is clear: closed-loop, resource-efficient, and high-performing.

Monomaterial Design

For a circular textile economy, design is just as important as disposal. Monomaterial clothes, made of a single fibre type, are easier to recycle. When a textile is made of two materials, it is harder to separate, contaminating recycling streams. The shift toward mono-fibre design helps create cleaner recycling loops.

Material Innovation

The shift toward circular fashion starts long before a garment hits the shelf; it begins with the materials we choose. Innovators in fashion are rethinking fabric choices and choosing what can be reused, remade, and truly recycled. Whether it’s bio-based fibres like hemp and bamboo or high-grade rPET chips, the shift isn’t just about textiles, it’s about creating a system that values regeneration over disposability.

Circular Supply Chains

Are your supply chains built to regenerate or just sustain?

The real potential of circular fashion extends beyond materials. It's about creating a system that integrates design, production, and recycling. That’s how we truly close the loop. This includes:

- Reverse logistics: Coordinating returns of textile waste.

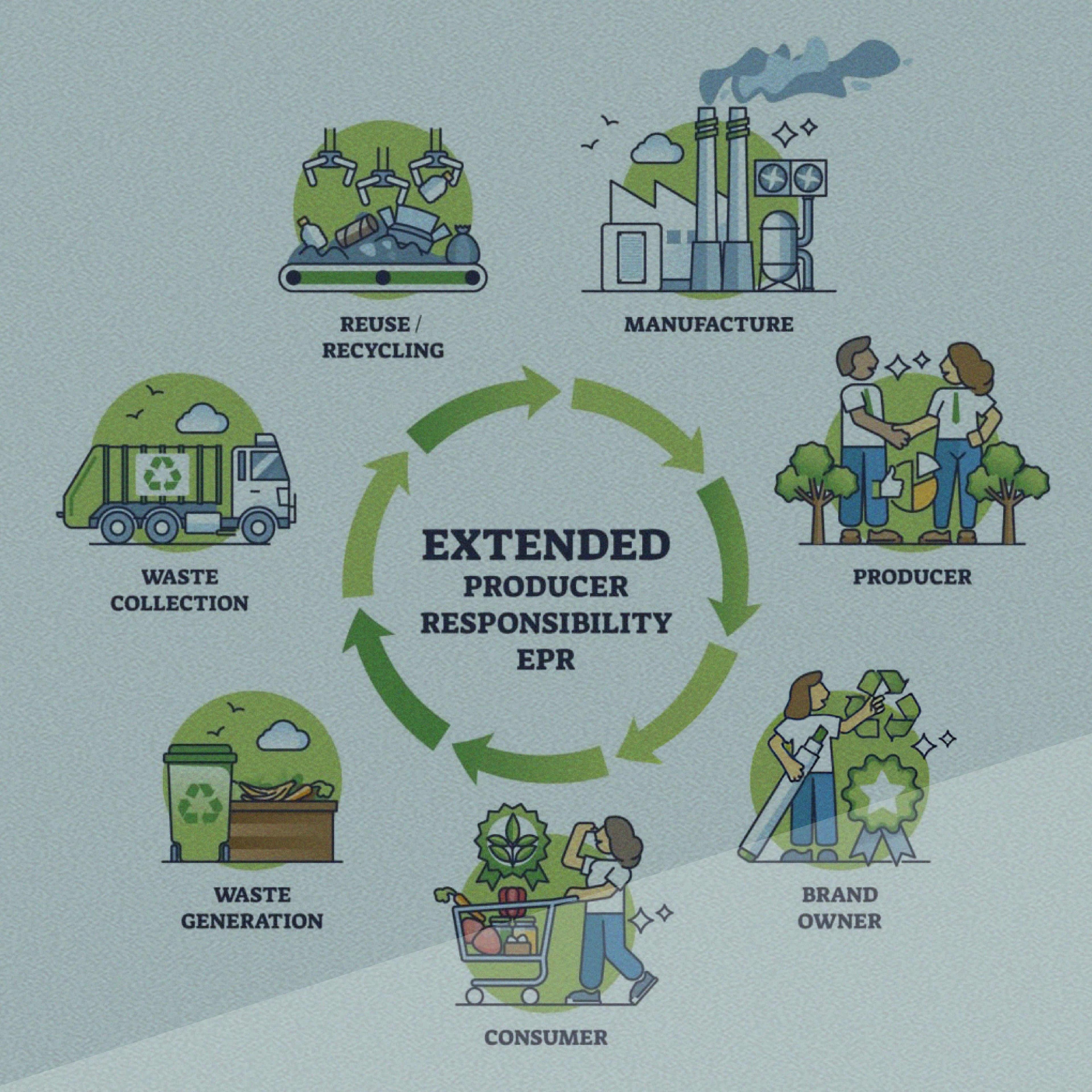

- Extended Producer Responsibility (EPR): Where brands collect garments post-use..

- Closed-loop manufacturing: Sensors and design ensure recyclability is part of production.

JB rPET plugs into these systems by supplying traceable rPET, supporting recycling infrastructure, and educating brand partners about quality and compliance.

Rethinking Fashion Economics

Innovative models drive circularity:

- Take-back programs (e.g., Patagonia Worn Wear)

- Clothing‑as‑service (e.g., Rent the Runway)

- Refurbish/repair services transitioning garments from single use to multiple uses.

These models preserve material life, reduce resource demand, and foster customer loyalty. Using certified materials like JB rPET gives credibility to these offerings.

Consumers as Co-creators

Consumers hold immense power. Here’s how they can contribute too:

- Buy less, choose wisely, and value longevity over trends.

- Repair, restyle, and care for your clothes.

- Donate, sell, or swap unworn items.

- Support brands using verified recycled materials

Educating consumers builds demand for circular products and helps scale systems.

Policy & Market Momentum

Regulatory forces are aligning:

- California’s textile recovery law (2024): In a big step forward, California now requires fashion brands to take responsibility for the clothes they sell, even after they've been worn. This means setting up proper systems to collect, reuse, or recycle used garments, helping keep textiles out of landfills.

- EU’s Ecodesign roadmap: The European Union is making sustainability a must, not a maybe. Its Ecodesign for Sustainable Products Regulation ensures that all textiles entering the EU meet minimum environmental standards, from how they’re made to how long they last.

- Extended Producer Responsibility (EPR) policies in India and EU: EPR policies hold brands operationally and financially accountable for the management of their products after use. In the textile industry, it entails implementing return, recycling, and reuse methods to relieve customers and communities of the waste load.

- The T2T recycling market has a forecast estimate of $9.4 billion in 2027, as per Technical Textiles today.

Conclusion

Circular fashion isn’t just a big idea for the future; it’s something we can act on today. It runs on a few foundational principles:

- Design: Emphasis on monomaterials, durability, and ease of maintenance.

- Technology: Using textile-to-textile (T2T) recycling, new materials, and traceability tools.

- Infrastructure: Developing systems for reverse logistics, certifications, and closed-loop operations.

- Business Models: Promote take-back programs, leasing, and product refurbishment.

- Consumers: Enabling individuals to be informed, intentional, and actively participating.

- Policy: Regulation driving change and investment

As an rPET manufacturer in India, we at JB rPET are taking meaningful steps towards unlocking the full potential of what's discarded. By transforming used textiles and discarded plastic into high-quality rPET, we’re opening new possibilities for the industry. Each pellet we produce exemplifies our dedication to a circular textile economy, innovation, and impact. We've upcycled and diverted hundreds of tonnes of waste from landfills through innovative technology, an extensive textile-to-textile chemical recycling facility base, and collaborations in fashion and packaging. And this is just the beginning.

The future is circular, where each strand, from a bottle or an unused fabric roll, gets to become a part of something new. It begins with thoughtful design, moves on to transparent sourcing and careful manufacturing, and continues in the daily decisions we all make as makers, businesses, and individuals. This is the way fashion becomes a solution, not a problem.

Now, it’s time for you to think: Are you closing the loop, or just circling around the problem?