Chemical Recycling of PET: Why Going Backward is the Way Forward

Not too long ago, the story of PET plastic followed a predictable arc. Bottles, trays, and textiles were manufactured, consumed, collected, and then, at best, downcycled into lower-value products until they eventually ended up as waste. Mechanical recycling was the hero of that era, but even heroes have limits: quality degradation, limited input streams, and packaging formats that couldn’t be recycled at all.

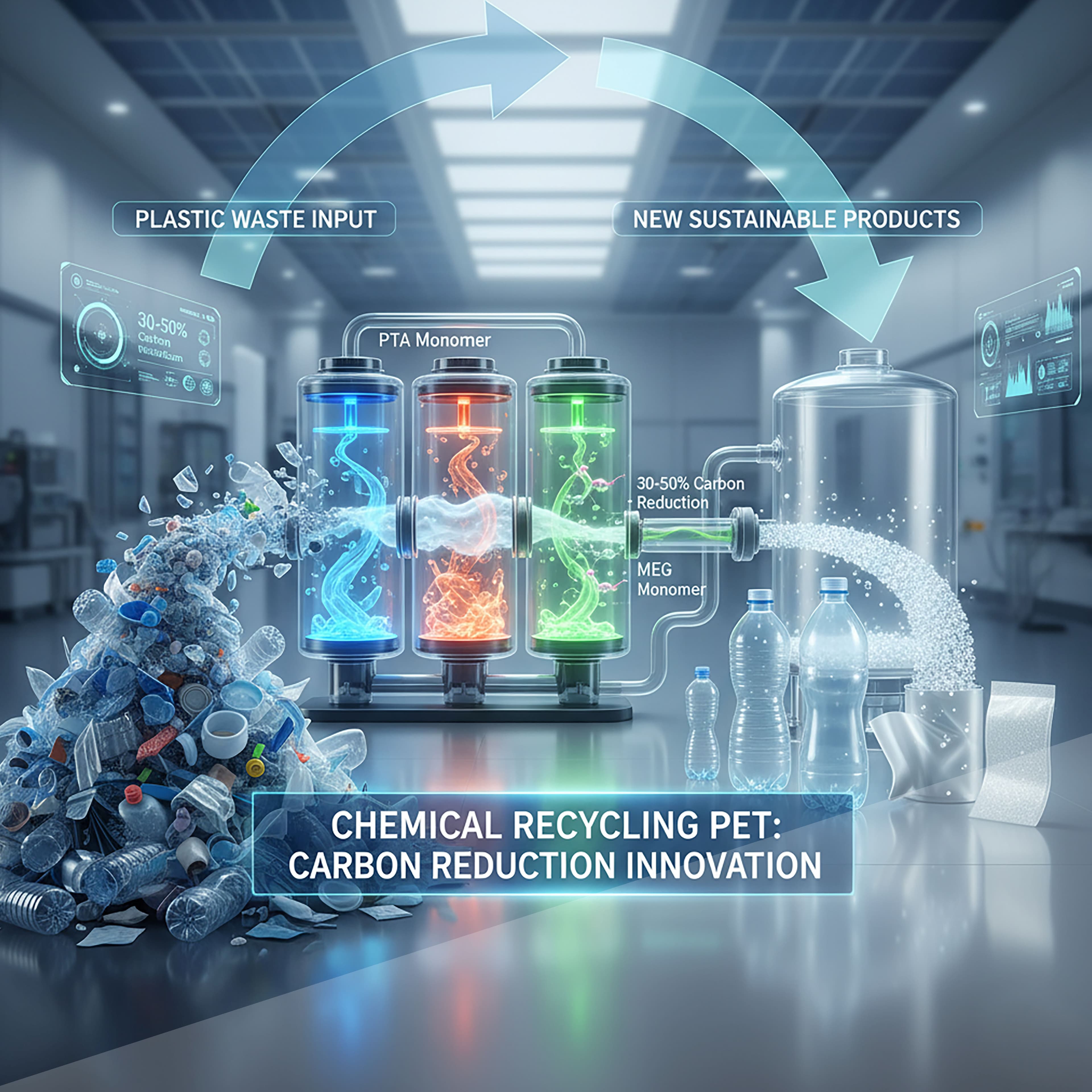

At JB rPET, we knew this narrative had to change. Because a recycling solution can’t be half-measures. That’s where the chemical recycling PET, and specifically the PET depolymerization process, steps in. Instead of simply re-melting plastic, it takes PET back to its molecular roots. Waste becomes monomer. Monomer becomes new, food-grade PET again.

Chemistry > Claims

When it comes to recycling claims, packaging can be dressed up with green labels and lofty promises, but molecules don’t lie. At the end of the day, the chemistry tells the truth. If PET is genuinely broken down through the PET depolymerization process, it returns to its pure building blocks, like BHET (bis-hydroxyethyl terephthalate), PTA (purified terephthalic acid), and MEG (monoethylene glycol). Think of it like dismantling Lego bricks: once you’ve broken them down, you can rebuild anything, again and again, with no loss of quality.

The result? rPET from chemical depolymerization that’s nearly identical to virgin PET, but without the environmental baggage.

Why It’s a Game-Changer

- Infinite loops: Unlike mechanical recycling, chemical recycling of PET doesn’t degrade quality. PET can go back to food-grade packaging, closing the loop instead of spiralling down. Tough-to-recycle formats unlocked: Coloured bottles, multilayer films, and contaminated packaging can be recovered, waste streams that previously went to landfills.

- Carbon advantage: Studies on the environmental impact chemical recycling PET show reduced emissions compared to making virgin resin from oil. While still evolving, it represents progress on the path to genuine decarbonization.

Environmental Impact of Chemical Recycling PET

The environmental impact of chemical recycling PET carries with it both great opportunities and significant considerations. On one hand, replacing virgin petrochemical feedstock with recovered monomers dramatically reduces:

- Carbon emissions associated with raw material extraction,

- Energy demand compared to producing PTA and MEG from oil,

- Plastic leakage, as previously unrecyclable waste streams, is captured.

Life Cycle Assessments (LCAs) have shown that chemical recycling can cut greenhouse gas emissions by 30–50% compared to virgin PET production. However, the actual footprint depends on process efficiency and the use of renewable energy in operations.

The Industrial Push

We’re not talking about lab experiments anymore. Now, depolymerization plants are popping up on roadmaps and investor decks, not just research papers. Industrial adoption chemical recycling PET has finally shifted gears from “let’s try” to “let’s build.” Companies are getting imaginative, transforming old wrappers and bottles into fresh, new materials that may be reused without the usual quality loss associated with regular recycling. Giants like Eastman, Loop Industries, and Carbios are expanding operations capable of processing thousands of tons of garbage each year. Governments are also supporting it, with EU regulations and brand commitments to utilize 25-50% recycled content in packaging.

This push isn’t just about tech, it’s about survival in a world where regulators, consumers, and supply chains all demand proof of circularity. And make no mistake, the companies that move first aren’t just cleaning up plastic, they’re claiming tomorrow’s competitive edge.

What This Means for Brands

1. Design smarter: Depolymerization has potential, but poor design, like multilayer packaging or non-recyclable dyes, still makes recovery harder.

2. Shift the story: It’s not enough to say “100% recyclable.” The real proof is in how much gets recycled into usable material.

3. Think carbon, not just plastic: The chemical recycling of PET isn’t just about waste, it’s about reducing the hidden emissions baked into packaging.

The Bigger Picture

Depolymerization isn’t a one-size-fits-all solution. It still requires energy, infrastructure, and smart waste collection systems. But it represents something bigger: a chance to move from linear to circular thinking. Instead of treating plastic as disposable, we’re treating it as durable chemistry, something that can be endlessly rebuilt.

Closing Thoughts

As an rPET supplier in India, we at JB rPET see chemical recycling of PET as more than an emerging technology; we see it as a way to rewrite the story of plastic. We’re building the infrastructure to make chemical depolymerization practical, scalable, and credible. We turn complex plastic waste into safe, food-grade rPET that goes beyond just meeting recycled content targets, it truly cuts carbon impact. By combining science with large-scale production, we show that sustainability and performance can grow together.

At its heart, this shift goes beyond recycling; it’s a call for responsibility. When waste becomes monomer, packaging doesn’t just tell a product story. It tells a climate story. And that’s the story the industry needs right now.