Textile Waste Recycling: How Brands Can Achieve Circularity

It starts with the sound of fabric rolling off machines.

The scent of freshly spun yarn fills the air. Another production day begins. Yet behind the rhythm of progress lies a quieter truth that most factories avoid talking about: the waste that piles up at the end of every shift.

Textile waste is no longer a byproduct. It is becoming the mirror that reflects how well the industry understands responsibility. For years, growth meant more production. Now, it means smarter recovery. The journey of textile waste recycling begins exactly where the story of efficiency seems to end with leftover fibers, rejected rolls, and discarded garments waiting for a second life.

Manufacturers and brand owners are rethinking what waste means, not as a burden, but as a bridge to circularity.

The Big Picture Behind Textile Waste Recycling

Textile waste recycling is the process of collecting and converting discarded textiles into usable raw materials that can re-enter production. It is reported by UNEP that every year, over 92 million tonnes of textile waste are generated across the world. That is enough to fill a garbage truck every second.

Large portions of this waste end up in open dumps, creating what are now called fabric mountains. In Chile’s Atacama Desert, entire dunes are layered with used clothes. In Ghana’s Kantamanto Market, imported textiles turn into waste faster than they can be sold. In parts of India, informal workers separate fabric heaps in search of reusable fibers.

These images remind the global textile community that responsibility does not stop once a product leaves the factory. The next phase begins where fabric scraps, old stock, and worn garments meet innovation. That is the purpose of textile waste recycling: to turn what once ended into what begins again.

Understanding the Roots of Waste

Textile waste has many sources, but it often starts from the simplest moments: a miscut panel, a batch rejection, an unsold collection. Every stage in the supply chain contributes to it.

1. Pre-consumer waste: leftover fabric cuttings, yarn ends, and off-cuts produced during manufacturing.

2. Post-industrial waste: surplus inventory or damaged goods that never reach the market.

3. Post-consumer waste: discarded garments or household textiles after their use.

It is imperative to note that change begins when fabric waste management shifts from disposal to recovery.

Factories that monitor their scrap flow, install automated sorting lines, and work closely with recyclers can create measurable value. What once filled warehouses can now feed future production. That mindset turns waste into material, not memory.

The Science of Textile-to-Textile (T2T) Recycling

Textile-to-Textile recycling (T2T) is a process where old fabrics are transformed into new fibers for manufacturing. Unlike down-cycling, which produces lower-grade outputs, T2T keeps the fiber quality high enough for reuse in apparel and textiles.

There are two main routes:

- Mechanical recycling: fabrics are shredded into fibers that can be spun again into yarns. It is effective for cotton and polyester and is improving steadily in quality retention.

- Chemical recycling: blended or synthetic materials are depolymerized into their base molecules and rebuilt into new fibers. This method enables purity restoration and long fiber strength.

T2T connects directly to post consumer textile recycling, closing the loop between discarded garments and new production runs. Global innovators continue to refine this science, creating fibers that match virgin quality while reducing environmental load. The concept is straightforward: waste becomes feedstock, and feedstock becomes fashion again.

BONUS: A T2T Readiness Checklist gives manufacturers a practical lens to gauge where they stand.

- Have digital tracking for all waste streams (cotton, blends, synthetic).

- Maintain partnerships with local recyclers or fiber reprocessors.

- Integrate mechanical and chemical waste screening.

- Audit fabric waste monthly and record diversion rates.

- Design new product lines compatible with recycled inputs.

- Ensure staff training for fiber sorting and contamination prevention.

When Fabric Waste Management Meets Innovation

Modern fabric waste management goes beyond manual sorting. AI-powered color recognition, digital fiber identification, and moisture detection are transforming recycling accuracy. In many facilities, conveyor systems now classify fabric bales based on fiber composition within seconds. This automation allows recycling partners to separate cotton, polyester, and blends more efficiently, reducing contamination and improving recovery rates.

When factories adopt these systems early, they also strengthen their standing with international buyers seeking transparent and sustainable textile supply chain partners. Waste data becomes an asset, a measurable indicator of progress and compliance.

Visibility leads to collaboration, and collaboration brings innovation. The more traceable the waste, the stronger the opportunities for regeneration.

A World Overflowing: The Global Dump Dilemma

The volume of textile waste keeps growing faster than the world can handle. What’s meant to be reused often travels across borders, only to end up discarded again. This is a cycle that looks circular but rarely is.

Once they reach developing countries, local systems struggle to manage them. Landfills near coastal cities in Africa and Asia now contain piles of clothing that stretch for kilometers. Each monsoon or rainfall releases dyes and microfibers into nearby rivers and soil.

The problem is no longer invisible. It is global, and it carries reputational and operational implications for every brand that operates within the textile value chain. To maintain trust, manufacturers are turning toward circular textile solutions that minimize waste before it leaves the factory gate.

Textile Waste Management Market Snapshot (2025)

| Segment | Market share (2024) | Growth Forecast (20230 CAGR) | Region Leading |

| Pre-consumer waste | 63% | 6.1% | Asia (China, Vietnam, India) |

| Post-consumer waste | 37% | 9.8% | EU, North America |

| Mechanical recycling | 70% | 4.5% | Developing markets |

| Chemical recycling | 30% | 10.2% | Europe, Japan, Gulf |

Where India Stands in Textile Waste Recycling

India’s textile sector continues to balance scale, innovation, and resource responsibility. The country generates an estimated 7.8 million tonnes of textile waste each year across spinning, weaving, and garmenting processes. A significant portion of this waste still moves through informal handling or landfill routes, though India remains recognized for its strong base in mechanical textile recycling practices.

The town of Panipat, Haryana operates as one of Asia’s largest textile recycling hubs, where a substantial volume of discarded garments is converted annually into yarn used for rugs, blankets, and outerwear. This region highlights how fabric waste management can support both livelihood and reuse. Other centers, including Tiruppur and Surat, are exploring circular textile solutions through organized waste segregation, improved dyeing systems, and water-efficient operations.

India’s recycling landscape blends long-established recovery methods with newer, technology-driven systems. Modern waste aggregators and textile recovery facilities (TRFs) are increasingly adopting structured processes to sort, grade, and redirect discarded fabrics into reuse, upcycling, recycling, and energy-recovery streams. Each stage contributes to a more sustainable textile supply chain, where traceability and material recovery continue to improve.

At the policy level, several discussions are underway. According to a 2025 readiness study by the Council for Scientific and Technical Policy, India is evaluating frameworks similar to global Extended Producer Responsibility (EPR) models. These would involve brand participation in financing collection and recycling mechanisms, promoting broader adoption of recycled textiles for brands. Initiatives under Bharat Tex 2025 and collaborative programs between UNIDO-GEF and the Ministry of Textiles are working toward pilot circularity zones and data-driven waste mapping.

These developments suggest gradual progress toward a coordinated system where post consumer textile recycling becomes a standard part of waste flow.

India’s trajectory combines industrial capacity with a long-standing culture of reuse. With its evolving policies, strong recycling foundation, and increasing stakeholder participation, the country continues to play a role in promoting textile waste recycling and supporting circularity across the broader Asia-Pacific landscape.

Inside JBrPET: Recycling Polyester Textiles for a Circular Future

Within this changing landscape, JBrPET Pvt Ltd focuses on enabling large-scale textile waste recycling through polyester recovery. The company collects both post-industrial and post-consumer polyester textiles and processes them into regenerated materials suitable for textile applications.

Each fabric lot undergoes sorting, cleaning, and precision treatment before conversion into high-quality recycled polyester. These recovered materials are used in the production of new fibers and fabrics that support closed-loop systems.

JBrPET’s model demonstrates how process-driven circular textile solutions can be built on consistency, technology, and traceability. By bridging the gap between waste generators and fiber users, the company contributes to a more sustainable textile supply chain where polyester waste is not discarded but reintroduced as valuable input.

Through partnerships with manufacturers, brands, and logistic partners, JBrPET continues to expand its capacity for post-industrial and post consumer textile recycling, helping the industry build circularity from the inside out.

Before the process begins, each fabric lot received by JBrPET is evaluated for its composition, color, and potential recyclability. The focus remains on ensuring every batch enters a well-defined recovery path. Once verified, the textiles move through a series of controlled stages designed to convert waste polyester into high-quality regenerated material.

This transformation unfolds through the following textile-to-textile recycling process, where chemistry and process control work together to create reliable, circular outputs.

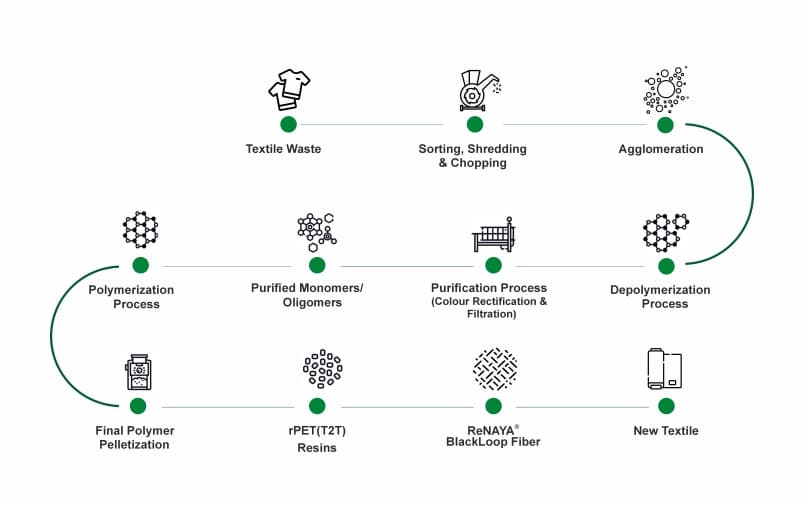

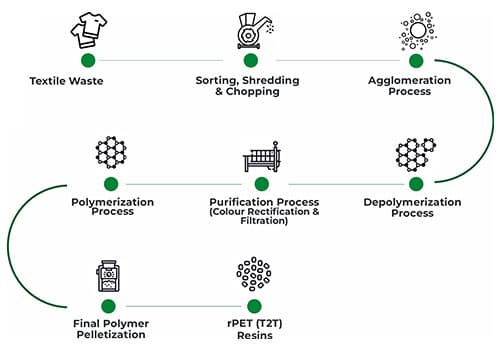

Textile-to-Textile Recycling Process

The process of textile waste recycling through chemical regeneration converts used polyester textiles into new, high-quality raw material. Each stage is designed to recover maximum purity while maintaining the molecular integrity required for textile applications.

1. Textile Waste Collection

Polyester-based textile waste is sourced from post-industrial and post consumer textile recycling channels. The material is pre-checked for contaminants, color variations, and fiber types to ensure consistent feedstock quality.

2. Sorting, Shredding and Chopping

The collected textiles pass through automated sorting lines that identify fiber composition. They are then shredded and chopped into uniform flakes or fiber pieces, creating a manageable base for subsequent treatment.

3. Agglomeration

The shredded fibers are heated under controlled conditions to form compact granules. This stage improves density and prepares the material for chemical breakdown, helping stabilize input for continuous processing.

4. Depolymerization

Through a specific combination of temperature and catalyst systems, polymer chains within the polyester are separated into their original monomers. This allows complete recovery of the base molecules, ready for purification.

5. Purification (Colour Rectification and Filtration)

The recovered monomers undergo color correction and multi-stage filtration. Residual dyes, additives, and particulate impurities are removed to produce a clean, colorless feedstock for polymer reconstruction.

6. Polymerization

The purified monomers are re-linked into long polymer chains through controlled polymerization. The result is a regenerated polyester resin with structural and performance characteristics equivalent to virgin PET.

7. Final Polymer Pelletization

The regenerated polymer is cooled, solidified, and pelletized into rPET (T2T) resins. These resins are then ready for use in fiber extrusion and fabric production, completing the textile-to-textile cycle.

This process enables continuous material recovery, supporting circular textile solutions and strengthening the sustainable textile supply chain. Each stage contributes to higher fiber circularity, reduced dependence on virgin materials, and measurable progress in textile resource efficiency.

How Circular Textile Solutions Create Value

Circularity delivers both environmental and business value. Manufacturers implementing circular textile solutions reduce dependency on virgin raw materials, manage costs more predictably.

A circular process typically includes:

- Collection and sorting: used textiles are identified and separated by fiber type.

- Material recapture: fibers are recovered mechanically or chemically for new yarn production.

- Design adaptation: products are created for longevity and recyclability.

- Reverse logistics: systems are built to return post-use garments for regeneration.

This chain keeps materials circulating within the economy and minimizes new resource extraction. For brands, adopting recycled textiles for brands enhances traceability and aligns with evolving global standards on waste accountability.

Circularity is not an aspiration anymore; it is a business framework that drives continuity and credibility.

Reinventing the Sustainable Textile Supply Chain

A sustainable textile supply chain connects every part of the value cycle including raw material sourcing, production, logistics, reuse, and recycling.

Building such a system requires three key actions:

1. Transparency: understanding and recording the origin and movement of every material.

2. Technology integration: digital platforms for waste tracking, material traceability, and lifecycle reporting.

3. Collaboration: joint programs between recyclers, brands, and manufacturers to ensure closed-loop flow.

When these practices combine, they create measurable impact. A brand that tracks its post consumer textile recycling performance shows responsibility and preparedness for future regulatory shifts. A recycler that maintains clear documentation becomes a reliable link in global sourcing networks.

Circular supply chains transform reputation into resilience.

Recycled Textiles for Brands: From Waste to Worth

Modern technology has redefined what recycled textiles for brands can achieve.

Today’s regenerated fibers offer softness, strength, and consistency comparable to virgin materials. Mechanical and chemical processes now preserve fiber integrity better, enabling recycled polyester and cotton to meet mainstream quality standards.

The global market for recycled textiles continues to expand, driven by consumer demand and legislative momentum. Between 2025 and 2035, the market is expected to grow from USD 5.1 billion to USD 7 billion, showing steady progress.

For brand owners, using recycled materials is more than a sustainability statement. It is a pathway to reliable sourcing and long-term cost stability. For manufacturers, it creates alignment with global buyers seeking proven circular practices.

When regeneration becomes routine, the line between waste and resource fades completely.

A New Mindset: From Waste to Loop

Every transformation begins with a mindset shift. Waste only becomes waste when it is ignored.

In factories that embrace circularity, discarded textiles are mapped, measured, and moved back into the system. Transparency dashboards track every bale, every scrap, and every regenerated fiber. Collaborations with recyclers create visible proof of progress.

Textile waste recycling is not a side project; it is becoming the foundation of sustainable growth. The path forward is built on accuracy, traceability, and accountability. Each recycled thread tells a story of an industry learning to care as much about what it makes as about what it leaves behind.

When that culture takes root, circularity stops being a goal and becomes a way of working.

From Textile Waste to T2T Resins

The textile industry’s next chapter depends on how efficiently it turns waste into value. JBrPET contributes to this shift by converting polyester textile waste into T2T resins that can be reintroduced into the supply chain.

Each batch produced follows a structured, traceable process that prioritizes material recovery and consistent quality. As global demand for circular materials grows, partnerships between recyclers, manufacturers, and brands are shaping the textile economy.

For more details or collaboration opportunities, visit www.jbrpet.in or reach out to our team to understand how textile waste recycling can integrate seamlessly into modern production systems.

FAQs: Textile Waste Recycling and Circularity

1. What is textile waste recycling?

It is the process of collecting, sorting, and converting discarded textiles into reusable fibers or materials. This keeps fabrics in use longer and supports a circular production system.

2. How does fabric waste management support sustainability?

Effective fabric waste management reduces landfill pressure and resource demand. It tracks waste streams to recover materials and guide future recycling decisions.

3. What is T2T recycling?

Textile-to-Textile (T2T) recycling converts old textiles directly into new fibers that can be spun again, helping brands close the production loop.

4. Why is post consumer textile recycling gaining importance?

Post consumer textile recycling targets used garments that would otherwise become waste. It transforms end-of-life products into new inputs for manufacturing.

5. How do circular textile solutions benefit manufacturers?

Circular textile solutions improve material efficiency, reduce virgin fiber dependency, and strengthen compliance with sustainability benchmarks.

6. What makes a supply chain sustainable?

A sustainable textile supply chain ensures traceability, renewable resource use, and responsible waste management from raw material to finished product.

7. Why should brands invest in recycled textiles?

Using recycled textiles for brands aligns with global sustainability policies and creates long-term sourcing stability through resource recovery.