Behind the Label: How to Tell If Your rPET Is Truly Recycled

Adopted by industry giants such as Adidas and Coca-Cola to fashion and packaging, recycled PET (rPET) is now one of the most trending materials in the fashion and packaging space. From "100% recycled" plastic bottles to eco-friendly activewear, "rPET" is a story of circularity. But how do we actually know that it is true?

The truth is that without proper verification mechanisms, brands risk falling into the trap of greenwashing, misleading consumers and regulators alike. We, at JB rPET, are here to help determine what's real, what's not, and how to spot it, supported by science and examples from India.

What Exactly Is rPET?

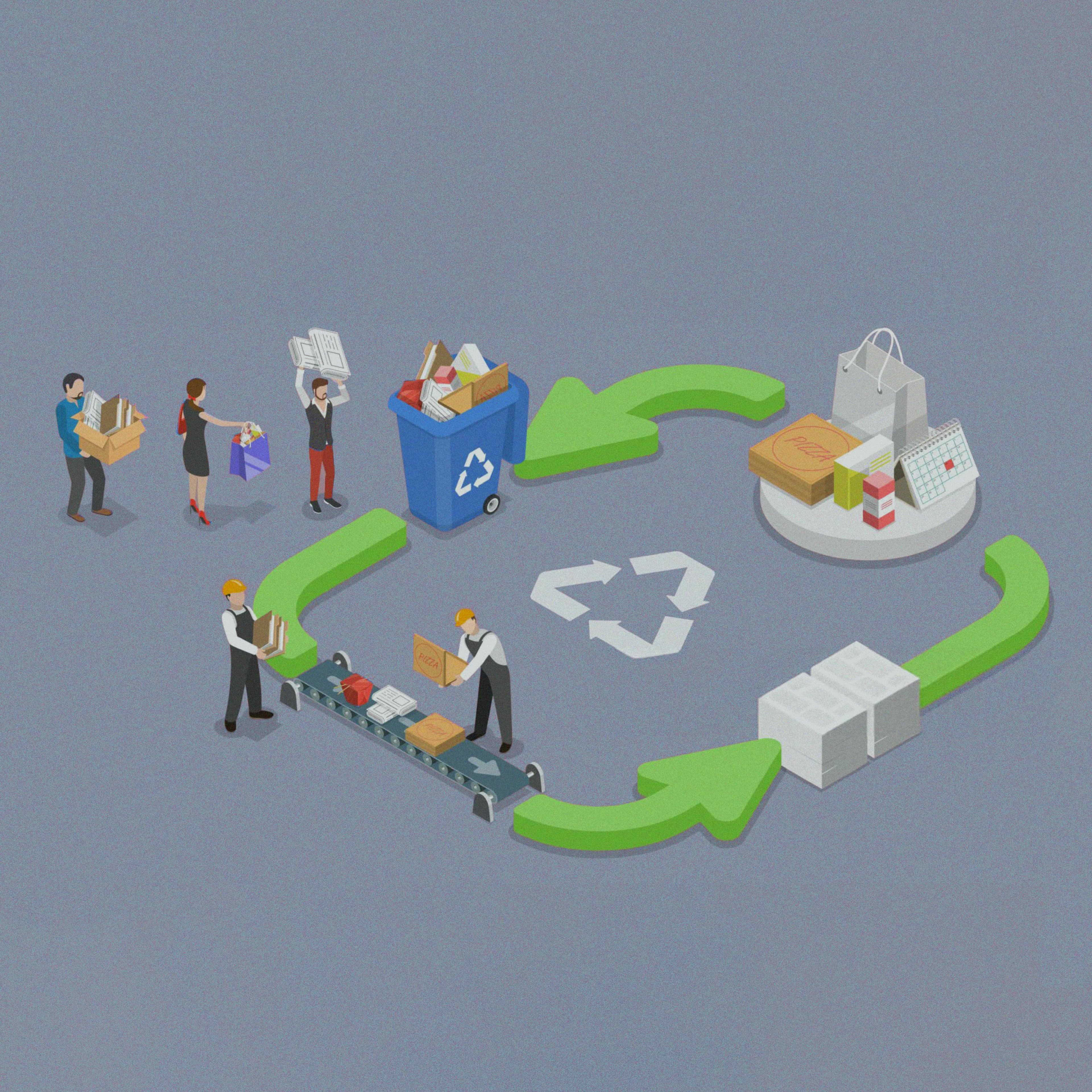

Simply put, rPET (recycled polyethylene terephthalate) is recovered plastic, commonly from discarded PET bottles or containers, which is broken down into flakes or pellets and used again in new products. Post-consumer rPET is produced from plastic retrieved after public consumption, and post-industrial rPET is retrieved from scrap created during the manufacturing process.

But the twist is that certain materials bearing the word "recycled" could actually consist of a very large proportion of virgin PET, particularly in nations with poor traceability systems.

India’s Regulatory Lens: What the FSSAI and BIS Say

India is among the few nations in the Global South to formally pursue the regulation of recycled PET, particularly for food-contact packaging

In 2024, the Food Safety and Standards Authority of India (FSSAI) released guidelines that permit rPET for use in food-contact packaging under stringent conditions. These include:

- Use of post-consumer PET bottles only (no mixed plastics, no industrial waste).

- Advanced recycling processes with proven decontamination efficiency.

- Mandatory migration and sensory tests to detect any toxic residues.

- Traceability systems to track the origin, processing, and end use.

For common (non-consumer) purposes, India does have standards, such as the Bureau of Indian Standards’s (BIS) IS 14534 for plastic recycling. But in industries such as textiles, where FMCG regulations are not quite as stringent, these standards tend to fall through the cracks.

Key Testing Methods to Detect Genuine rPET

To verify whether a product truly contains recycled PET and to what extent, several technical methods are used by labs and certifiers:

IPA Marker Testing (Isophthalic Acid Profiling)

IPA is present only in clothing or plastics that are created from recycled material. If the product actually has recycled PET, then it will have quantifiable amounts of IPA. Otherwise, virgin plastic generally does not have this indicator.

JB rPET offers IPA-based verification specifically for brands looking to confirm recycled content in supply chains. For instance, if a textile says it’s made from “100% rPET,” IPA testing can validate that claim against a benchmark database of virgin vs. recycled PET.

Chain-of-Custody Audits

Chemical testing is only one piece of the puzzle. To guarantee recycled content throughout the life cycle, brands need to prove:

- Source documentation (such as invoices from recyclers)

- Processing steps (e.g., extrusion, decontamination records)

- Batch traceability to the finished product

This is especially important in countries like India, where formal and informal waste systems intersect in complex ways.

Migration, Extraction & Sensory Testing

Especially for food-grade rPET, labs must conduct:

- Migration tests to measure chemical leaching into food simulants.

- Extraction tests to check for organic residues or odour.

- Sensory tests to ensure no off-flavour or appearance.

FSSAI mandates that rPET for food contact must have:

- Migration values < 10 µg/kg in food simulants

- Total residual contaminants < 220 µg/kg in the resin

- ISO-compliant testing via NABL-accredited labs

Certifications & Global Benchmarks to Look For

Saying you use rPET is one thing. Backing it up with third-party validation is what you really need to build trust. These include:

- Global Recycled Standard (GRS)

Tracks recycled content and ensures social, environmental, and chemical practices in production.

- Recycled Claim Standard (RCS)

Focuses on verifying recycled content in the product itself.

- FSSAI/FDA/EFSA Compliance

For food-contact materials, certification from regulatory bodies ensures consumer safety.

GRS or RCS certification is more likely to maintain transparency through documentation, testing, and supply chain audits.

What Brands & Consumers Should Watch Out For

Here’s a quick checklist for identifying greenwashing vs. genuine rPET:

| Claim |

Red Flag |

What to Ask/Check |

| Made from recycled plastic |

No mention of % or type |

Ask for a specific content breakdown |

| rPET approved |

No lab or certifier named |

Look for test reports or certifications |

| Recycled content verified |

No source or traceability |

Request batch-level trace logs |

| Food-safe rPET |

No FSSAI approval |

Demand test results from NABL/ILAC labs |

| 100% rPET clothing |

No IPA data or audit trail |

Verify IPA marker test and supply chain |

Real-World Challenges in India

India processes over 9 million tonnes of plastic waste annually, yet much of it ends up downcycled or informally managed. Some challenges in verifying true rPET include:

- Lack of real-time waste traceability from informal collection channels.

- Fragmented recycling operations with varying degrees of processing quality.

- “Virgin blending” practices, where virgin PET is mixed with recyclate but sold as 100% rPET.

However, the rise of tech-integrated recyclers is beginning to change that, offering better data, cleaner input streams, and traceability tools.

Conclusion

“100% recycled” sounds great on a label. Claims are easy to make; proof is what matters. If you're sourcing, producing, or just picking something off a shelf, knowing what you're getting shouldn’t be too much to ask. Demand clarity. Look for lab-verified recycled PET content, IPA marker tests, regulatory compliance, and ethical sourcing.

At JB rPET, we believe that being truly recycled goes beyond just a label; it’s about integrity, science, and responsibility. That’s why every batch we produce is backed by verifiable data, tested through methods like IPA testing, and supported with transparent documentation. We know that recycled content claims can be easily made, but proving them is what sets a credible rPET suppliers apart. Because in the end, recycling isn’t just about what we say, it’s about what we do, and how we prove it.