Home / Recycled BoPET vs. Virgin Materials: Making the Better Choice For a Sustainable Tomorrow

Recycled BoPET vs. Virgin Materials: Making the Better Choice For a Sustainable Tomorrow

Gone are the days when sustainability was an option. It is now a vital requirement for both organisations and consumers. They are increasingly focusing on environmentally responsible solutions, and JB rPET is at the forefront of this shift. As one of India’s top chemical recycling companies, we specialise in high-quality recycled pellets that are suitable for a wide range of applications, including flexible packaging films such as BoPET.

The most crucial question is whether brands should acquire recycled or virgin BoPET, and why.

This article distinguishes between recycled and virgin BoPET, providing significant insight into why recycled BoPET is quickly becoming the material of choice to suit market demands and environmental aims.

-

Food Packaging

- – Virgin BoPET: Virgin BoPET can only be made by extracting petrochemicals such as terephthalic acid and ethylene glycol. This process is energy-intensive and heavily reliant on fossil fuels, which degrades resources and causes significant greenhouse gas emissions. Moreover, the entire lifecycle, from production through usage to disposal, is linear, thereby increasing the world’s landfill burden.

- – Recycled BoPET: The post-consumer PET polymers are the source of recycled BoPET. In this process, one can save considerably in energy and carbon emissions, divert waste from landfills and the ocean, and come closer to saving considerably in new resource dependency. Recycling BoPET reduces environmental stress by converting waste into reusable materials, establishing a circular lifecycle

-

Achieving Cost Efficiency and Stability

- – Virgin BoPET:Costs can be unexpected because the manufacturing of virgin BoPET is directly linked to changes in the price of petrol and oil. The financial burden on businesses that use virgin resources is also anticipated to increase as environmental regulations become more stringent, either through increased taxes, compliance fees, or penalties.

- – Recycled BoPET: Recycled BoPET uses waste as its main input, making it less vulnerable to changes in the price of raw materials. To further cut expenses, numerous governments and organisations now provide tax credits and incentives to encourage the use of recycled materials. Because of these advantages, recycled BoPET is a more secure and long-term option.

-

The Narrowing Quality Gap

- – Virgin BoPET:Virgin BoPET has long been favoured due to its exceptional strength, clarity, and thermal stability. However, the quality of recovered BoPET has greatly increased due to developments in recycling processes, and in many applications, it is now almost identical to its virgin counterpart.

- – Recycled BoPET: Recycled BoPET satisfies strict performance requirements thanks to modern recycling techniques like chemical recycling and enhanced purification. It is now appropriate for high-demand uses, such as industrial films and food-grade packaging, demonstrating that performance and sustainability can coexist.

- Recycled BoPET is becoming a more attractive alternative to virgin materials in a variety of industries due to the closing quality gap.

-

Building Consumer Trust Through Sustainability

- – Virgin BoPET:As global concerns for the environment increase, companies relying purely on virgin materials will also be exposed to reputational risks. Increasingly, consumers and stakeholders are holding companies accountable for their environmental footprint.

- – Recycled BoPET: With the use of recycled BoPET, companies become sustainability leaders as they meet this consumer demand for eco-friendly products. It falls within the broader themes of ‘circular economies,’ in which materials are reused rather than thrown away, improving corporate social responsibility initiatives.

- It aids in improving brand reputation by enhancing stakeholder trust and responding to the increasing demand for sustainable solutions.

-

Navigating Policies For a Competitive Edge

- – Virgin BoPET:Governments worldwide are legislating to tax virgin material, promote recycling, and prohibit plastic waste. Those who do not adapt will be non-compliant and with increasing operating costs.

- – Recycled BoPET: Recycled BoPET is in tandem with international legislative trends, including the growing acceptance of Extended Producer Responsibility laws, and the European Union’s Circular Economy Action Plan. Businesses that use recycled materials will end up better placed to remain ahead of the competition and will be benchmarked against present and future legislation.

- Using recycled BoPET in compliance with regulatory requirements guarantees market competitiveness and business continuity.

Therefore, recycled BoPET helps firms save money and avoid trouble with the law.

The Road Ahead

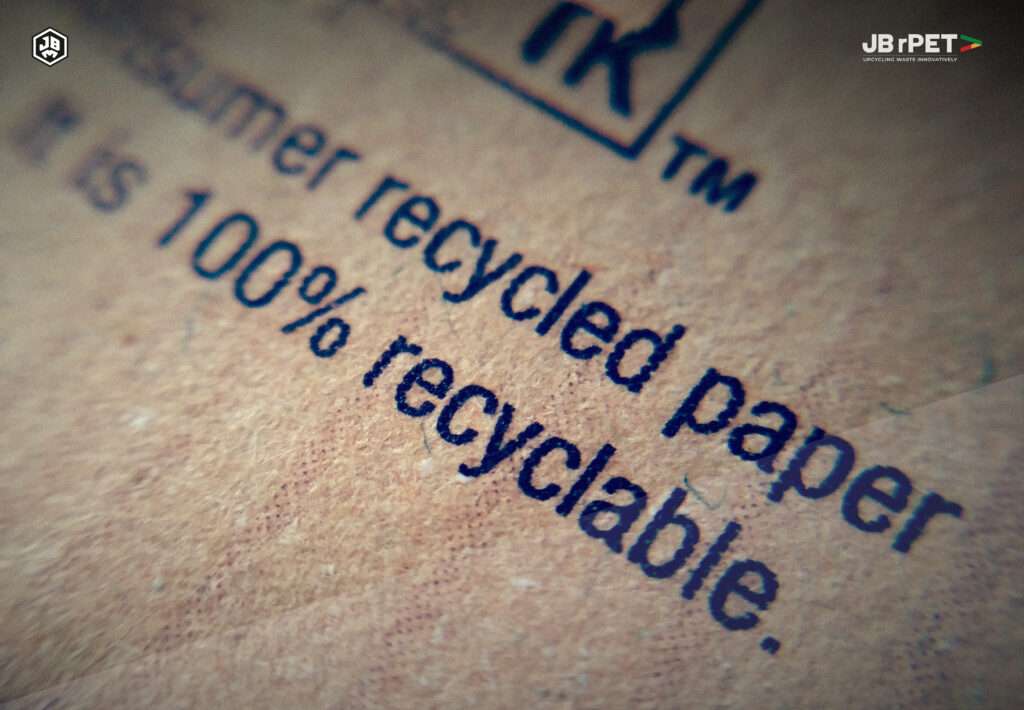

Many individuals are unaware of the distinction between virgin and recycled BoPET, particularly buyers who are more concerned with a product’s recyclable nature than its composition. Clearer labelling and improved communication are required to raise awareness. The supply chain should be educated regarding the process, using certifications such as Global Recycled Standard, to let consumers know about the environmental implications of recycling BoPET, such as less energy usage and carbon footprint. The labelling of recycled material can also be used to gain brand trust. The more governments and companies strive toward sustainability, the more people are going to have a clear idea of what virgin BoPET and recycled BoPET are.

Switching from virgin to recycled BoPET is no longer an ethical choice alone but a strategic imperative. The bottom line is that his business can reduce the environmental impacts and remain competitive in a sustainability-driven economy.

We, at JB rPET, urge you to review your supply chain, discuss joint ventures with recyclers, and begin incorporating recycled BoPET into your operations. It’s never too late if we unite for the cause.